Ensure Project Success: The Relevance of Aftermarket Construction Parts Purchase

Ensure Project Success: The Relevance of Aftermarket Construction Parts Purchase

Blog Article

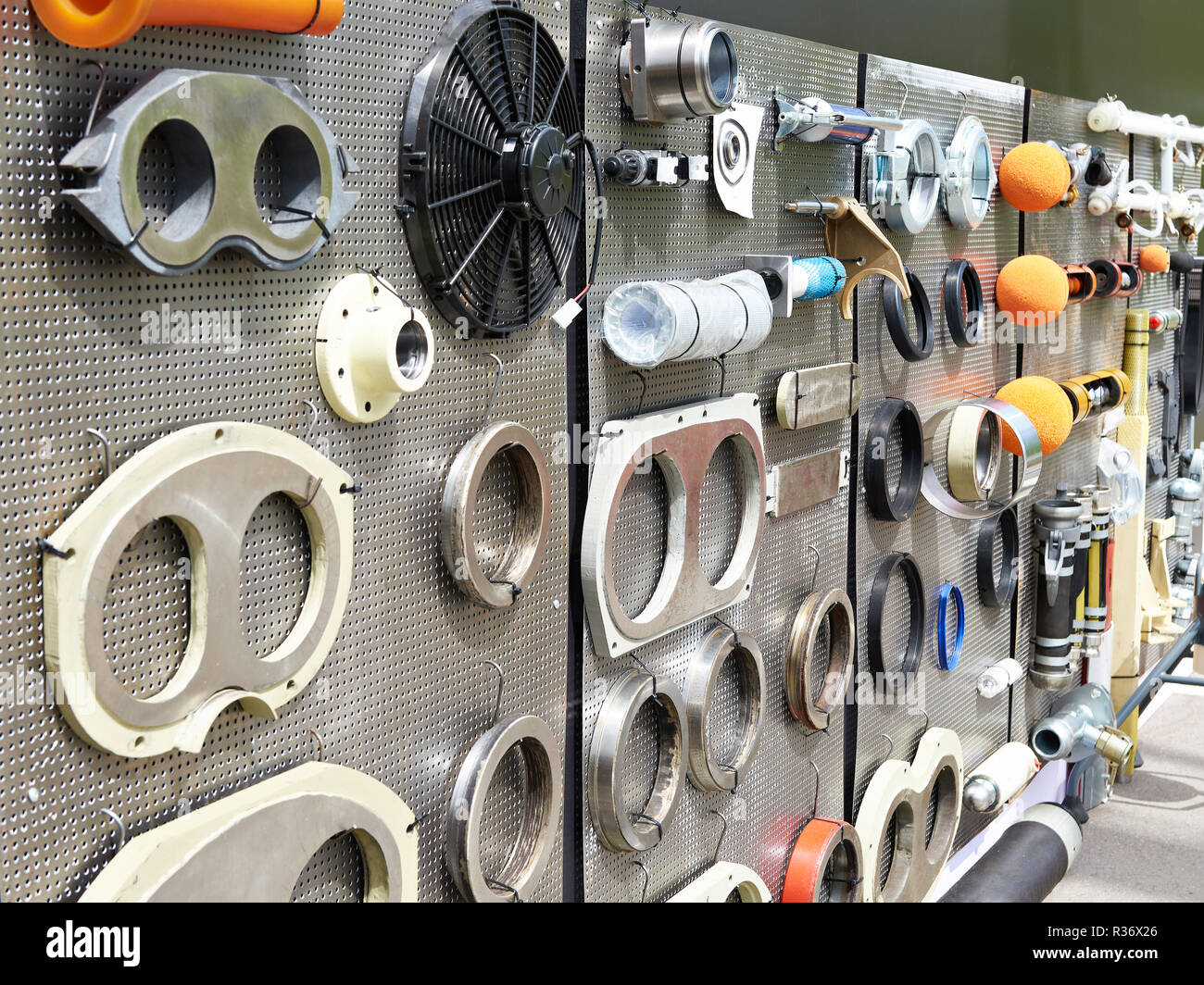

Boost Effectiveness With Aftermarket Parts: an Overview for Heavy Machinery Owners

Benefits of Aftermarket Components

Owners of hefty machinery can delight in many benefits by deciding for aftermarket parts over initial equipment supplier (OEM) parts. Among the key advantages is expense savings. Aftermarket components are usually more economical than OEM components, allowing machinery owners to reduce repair and maintenance expenses without endangering on quality. Furthermore, aftermarket parts commonly feature guarantees, ensuring that purchasers are shielded in case of any type of issues or problems.

Given that aftermarket makers specialize in generating certain elements, equipment owners have accessibility to a wider range of choices to fit their needs. Aftermarket components are recognized for their quality and dependability, with lots of conference or surpassing OEM standards.

Finally, choosing aftermarket parts can also cause faster repairs and decreased downtime. With easier availability and fast delivery options, equipment owners can get their equipment up and running once again promptly, minimizing disruptions to their operations.

Choosing the Right Aftermarket Components

When considering aftermarket parts for hefty machinery, it is vital to prioritize compatibility and high quality to make certain optimal performance and longevity of the devices. Choosing the best aftermarket parts can be a crucial choice for heavy machinery proprietors as it directly impacts the performance and reliability of their devices.

Second of all, top quality must never ever be endangered when choosing aftermarket components (aftermarket construction parts). Opting for high-grade components ensures longevity, integrity, and overall efficiency of the equipment. It is advisable to source aftermarket components from reliable makers or vendors recognized for their top quality standards

In addition, considering variables such as warranties, customer testimonials, and compatibility with existing systems can additionally aid in making the best choice. By focusing on compatibility and high quality when selecting aftermarket parts, hefty machinery proprietors can enhance the performance and longevity of their equipment.

Installation and Upkeep Tips

For reliable procedure and longevity of hefty equipment, appropriate installment and normal upkeep are extremely important. When installing aftermarket components, make sure that you very carefully comply with the producer's guidelines to assure optimum efficiency. By prioritizing setup and upkeep procedures, you can take full advantage of the performance and lifespan of your heavy equipment, ultimately saving time and money in the lengthy run.

Cost-Effectiveness of Aftermarket Parts

Appropriate setup and normal maintenance are fundamental elements for heavy equipment owners aiming to analyze the cost-effectiveness of aftermarket components for their tools. While initial tools supplier (OEM) components are known for their high quality, aftermarket components use an even more affordable service without jeopardizing efficiency. The cost-effectiveness of aftermarket parts ends up being noticeable in different methods. Aftermarket parts are usually much more pop over here economical in advance, allowing owners to achieve cost savings on first acquisition prices. Additionally, these parts usually offer equivalent efficiency to OEM parts, making sure that the equipment runs efficiently without the requirement for costly substitutes. The availability of aftermarket parts my blog from a vast variety of suppliers advertises competition, leading to affordable rates and further expense financial savings for owners. By meticulously assessing the quality and compatibility of aftermarket get rid of their equipment, owners can strike an equilibrium between cost-effectiveness and performance, ultimately taking full advantage of the performance and durability of their hefty devices.

Optimizing Performance With Aftermarket Upgrades

To enhance operational performance and performance, hefty machinery owners can successfully maximize performance with calculated utilization of aftermarket upgrades. Aftermarket upgrades use the opportunity to tailor hefty machinery to certain operational needs, causing improved functionality and outcome. Updating elements such as engines, transmissions, hydraulic systems, and tracks can dramatically improve the overall performance of the machinery.

Regularly analyzing the performance of heavy equipment and determining areas where aftermarket upgrades can be advantageous is important for maximizing efficiency. By investing in high quality aftermarket components and upgrades, machinery owners can accomplish higher levels of performance, inevitably resulting in cost financial savings and improved functional outcomes.

Final Thought

To conclude, aftermarket parts use numerous advantages for hefty equipment proprietors, consisting of cost-effectiveness, boosted effectiveness, and customization choices. By selecting the appropriate aftermarket parts, following correct setup and upkeep procedures, and making best use of upgrades, hefty equipment proprietors can boost their devices's performance and long life. Buying aftermarket components can inevitably cause boosted efficiency and reduced downtime, making it a rewarding consideration for proprietors wanting to optimize their machinery procedures.

Owners of heavy machinery can take pleasure in countless benefits by deciding for aftermarket parts over initial equipment producer (OEM) components. Aftermarket components are commonly extra cost effective than OEM components, permitting equipment proprietors to minimize maintenance and fixing prices without endangering on high quality. By very carefully evaluating the high quality and compatibility of aftermarket parts with their machinery, owners can strike a balance in between cost-effectiveness and performance, ultimately making best use of the performance and durability of their heavy equipment.

In conclusion, aftermarket components offer many benefits for heavy equipment owners, consisting of cost-effectiveness, raised effectiveness, and personalization choices. By selecting the best aftermarket parts, complying with proper installment and upkeep procedures, and making the most of upgrades, heavy machinery owners can boost their devices's performance and durability.

Report this page